Call our trained professionals today!

News Calendar | |||

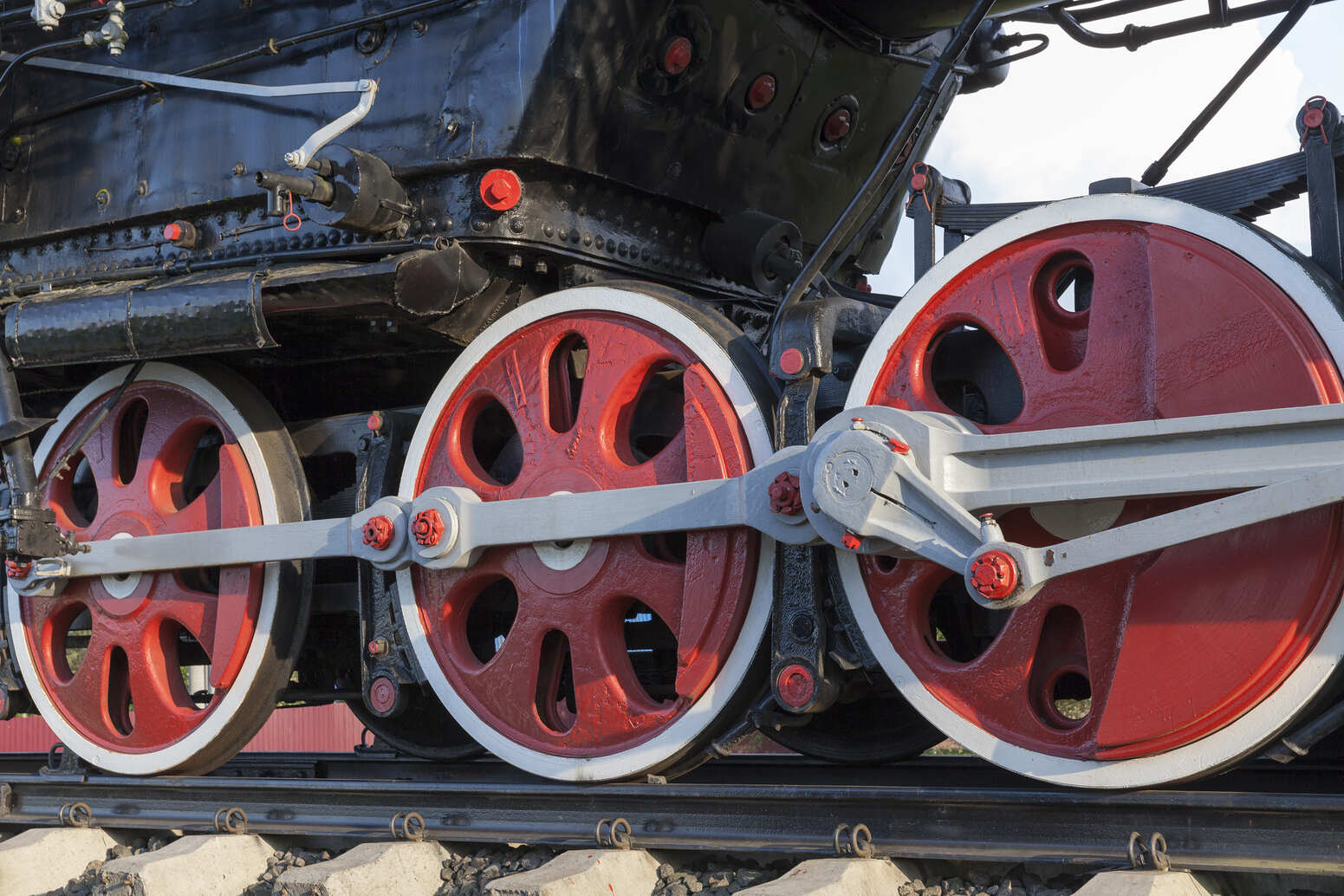

Railway Equipment Service Provider | Meeting Unique Railway Equipment Needs

Mar 04, 2024Custom fabrication stands as an indicator of innovation and precision within the rail industry, embodying its pioneering spirit. Railway equipment service providers boasting both craftsmanship and cutting-edge technologies are on a journey of providing tailor-made solutions beyond standard tracks. Custom fabrication in the railway sector showcases providers' extraordinary skill at crafting tailor-made solutions to suit the specific and individual requirements of their clients.

Innovative Parts and Solutions (IPS) understands the role that railway equipment service providers play in ensuring smooth rail operation, with top-of-the-line solutions provided to rail transportation. We take great pride in upholding high standards for quality, service, and safety through our team of expert professionals - providing precision machining, custom fabrications, heavy equipment service support as well as providing parts and tools.

Custom fabrication in the railway industry is an art in its own right, requiring precise evaluation of each project's needs before crafting unique solutions from scratch. In contrast to off-the-shelf components, custom fabrication allows railway equipment service providers to meet specific challenges presented by various projects with tailored solutions tailored precisely to them.

Each railway project presents unique challenges, and custom fabrication service providers work closely with their clients to assess every element of a project, from load-bearing capacities, environmental considerations, and safety requirements to aesthetic preferences.

Once we understand your project requirements, the design phase begins. Here, custom fabrication's artistry shows its depth: our experienced designers and engineers collaborate to devise solutions that not only meet technical specifications but also satisfy the visual and functional expectations of the client.

One of the key decisions in custom fabrication is selecting materials. Railway equipment service providers must strike a balance between strength, durability, and weight considerations when selecting their materials for custom fabrication projects. High-strength steel alloy materials are often used where resilience is of primary concern and can often be found as being best suited to meeting engineering standards while simultaneously optimizing performance.

Once designs and materials are decided upon, precision machining becomes the center of attention. Equipped with cutting-edge CNC technology and skilled machinists who employ it, precision machining transforms raw materials into precise components using meticulous cuts, drills, and bends executed with meticulous accuracy to meet initial design specifications and ensure a seamless end product.

Components are assembled carefully with meticulous care and attention to every detail to form the final product. Assembly is then further supported by strict quality control measures aimed at assuring structural integrity and meeting safety standards - this phase ensures that our custom-fabricated solution exceeds industry benchmarks.

Custom fabrication for the railway industry presents unique challenges. Continuous innovation must occur as new technologies come online, safety standards change, and client expectations become more demanding. Railway equipment service providers use these challenges as opportunities to push beyond what was thought possible and push forward their industry.

Custom fabrication stands as the cornerstone of innovation in railways, where each project brings with it unique demands. Railway equipment service providers combine artistry and technical know-how to craft solutions that go beyond the ordinary, from sturdy foundations for bridges to intricate staircase details - custom fabrication showcases how the industry adapts, creates, and elevates the rail travel experience itself. As progress moves us along its tracks, custom fabrication continues its role as an artful way to craft journeys with care and precision.

Innovative Parts and Solutions is your reliable Railway Equipment Service Provider in North America, boasting an unwavering commitment to excellence and offering cutting-edge solutions to the railway industry. From precision machining and customized fabrication projects to providing parts and tools on demand - IPS is here for you! Our dedication to quality, safety, service, and innovation ensures flawless rail operations! Contact our professionals now at (604) 465-8994 and experience firsthand the reliability and innovation that define IPS!